A gas turbine stripped down to nothing but its casing brings to mind a scene from an automaker’s assembly line: an empty chassis that’s full of potential. Next year, a GE team will seek to realize such potential at the 435-megawatt Tallawarra A power station, 60 miles south of Sydney on the New South Wales coast. The goal is to transform an existing GE turbine there into one that will be more efficient and require less natural gas to generate electricity.

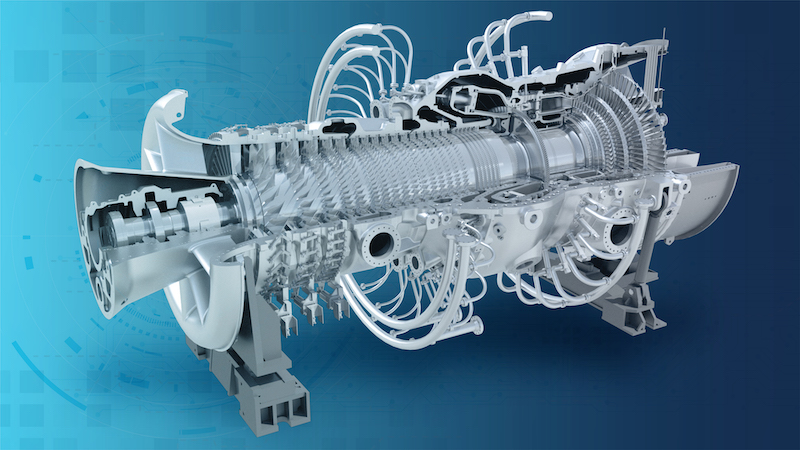

Starting with the bare shell of a GT26 power unit, they plan to fill it back up with a fresh turbine, advanced 3D-printed combustor architecture, and an innovative compressor that is expected to deliver less air to the turbine, constraining its power output to just the right level. That’s the moment the original GT26 will become a HE. HE stands for “high efficiency,” because, rather than aiming for a bigger boost in the unit’s power output, it targets a larger reduction in the natural gas going in.

The HE upgrade for the GT26 can also be thought of as “a force multiplier” for renewables, says Alex Evans, HE global commercialization leader at GE Gas Power. New South Wales is a big renewables state, with an renewables electricity output that now stands at a 20% share. It is also Australia’s most populous state, which makes it a major driver of the nation’s decarbonization path. But fluctuating renewables need a supportive partner to move smoothly and strongly through their ups and downs — to zig when they zag. Australia is a standout leader in rooftop solar, and it’s now estimated that an incredible 30% of detached homes have solar; the country generated 31 terawatt-hours (TWh) from solar in 2021, and wind wasn’t far behind, at 26 TWh. And all those roof-mounted black squares don’t just zig and zag: They spike, and crash, and spike again.

The componentry of the HE not only balances out the wild nature of solar, through tick-by-tick rapid response, but does so while taking the next big step in efficiency. According to Evans, engineers think about efficiency gains differently than you or I do. The great game in turbine development is not about achieving impossible improvements measured in increments of 10% or 20%, but rather 1% or 2%. “Your F classes” — to which the GT26 gas turbine belongs — “will typically have between 58% and 59% efficiency; combined-cycle and H-class, 60% to 64%. The HE is moving the F-class turbines into the H-class space for a fraction of the cost.” Evans pauses and reflects: “When you talk about a 2% number, to gas turbine engineers? They get really excited. They might even shout, ‘You can’t do that!’”

So it’s no surprise that the HE solution is spreading out to the rest of the world, finding its destiny in other geographies with a high number of renewables domains. There are HEs now deployed in Singapore (operated by Keppel), Japan (JFE Steel), and two in the U.K., at Enfield (Uniper) and Shoreham (Drax). “Enfield was the first, near London, and is a good example because of the high renewables penetration in the U.K.,” says Evans. While Australia is a country high in solar capacity, deriving 11.7% of its total electricity from solar in 2021 — compare that with 3.75% for the U.S. — the U.K. is a giant of wind power, which supplied nearly 21% of its electricity in the same year, according to the BP Statistical Review.

And if solar goes through zigs and zags, wind power volatility zooms right off the charts. Wind is the most unevenly distributed renewable energy source, with enormous supply coming in spikes over days or weeks that resolve again to long lulls. The ability of the HE to wrangle that volatility is winning converts. “The feedback we’ve had from power plant operators has been fantastic,” says Evans. “You can make an engineering masterpiece, but unless it works and makes the plant competitive, it’s no good.” What’s particularly satisfying, explains Evans, is that, now that Enfield and Shoreham have been upgraded to the HE platform, both stations have risen in the U.K.’s “merit order,” a grid concept that simply means they get called in to work before others. The HE is popular.

Balancing renewables, shoving older, less efficient power plants out of the way, and using less natural gas are now established victories for the HE. According to Evans, there’s an emissions improvement too. “You should expect about a 5% reduction,” he says. “And for a baseload plant, this reduction in carbon intensity would be equivalent to taking about 16,500 cars off the road.” Which means less CO2 in Australia, where emissions have already declined nicely, having fallen 9% from 2016 through 2021.

But the HE’s work is not done. Tallawarra A’s companion power station, Tallawarra B, is set to open later this year as Australia’s first dual-fuel gas-and-hydrogen plant. In 2025, EnergyAustralia, the operator of both plants, intends to start blending hydrogen at Tallawarra B, up to a 5% mix of hydrogen by volume. More exciting is that the operator has applied to the NSW government to establish on-site production of green hydrogen. And of course, that supply would also be available at Tallawarra A.

According to Evans, the HE will be just as adept at utilizing tricky, hard-to-handle hydrogen, whose tiny molecule is prone to escaping, making it very hard to contain. The upgrade to the HE “is all part of being able to handle higher-reactivity fuels, and that’s what hydrogen is: highly reactive. After all,” he adds, “it’s the smallest molecule in the universe.”