Industrial Software

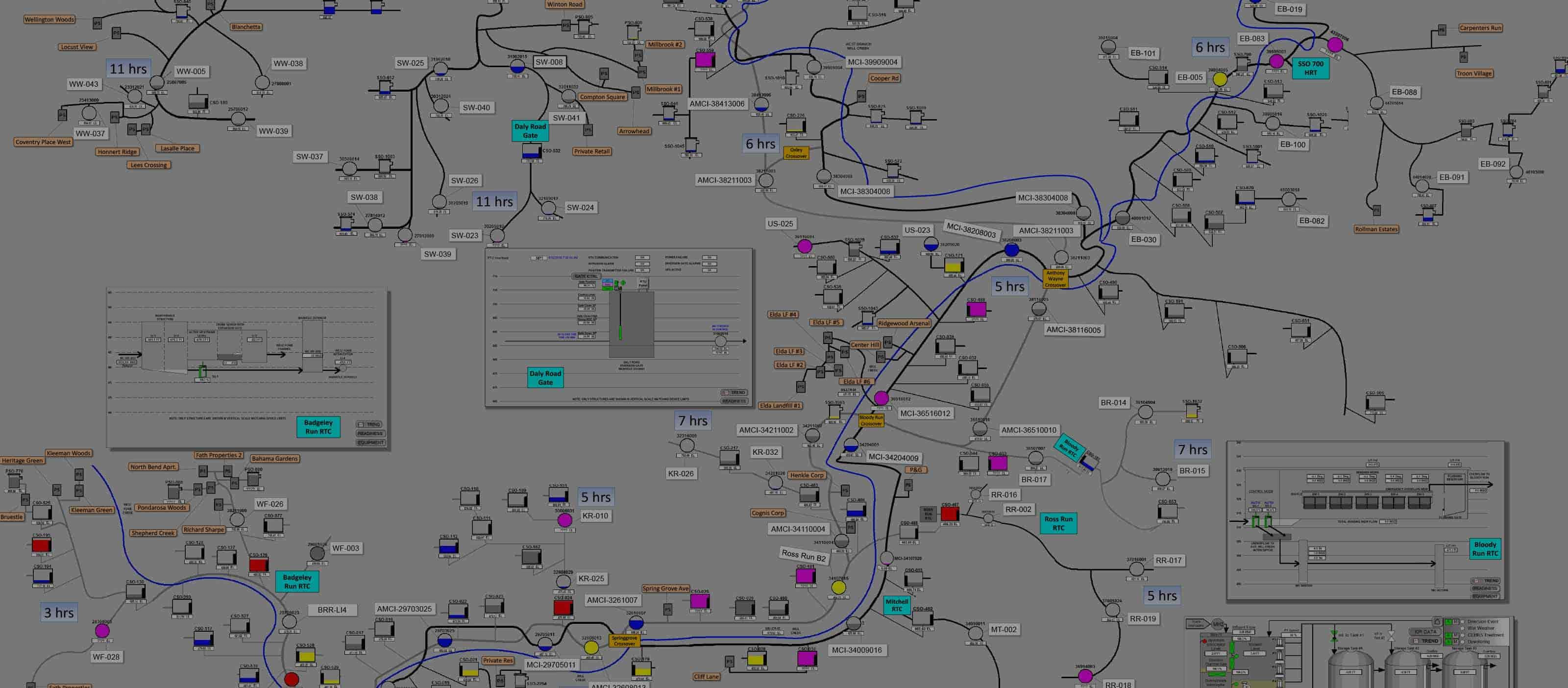

Proficy HMI / SCADA

Drive smarter operator decisions with model-based high performance HMI for faster response and development

View HMI/SCADA demo

What is HMI/SCADA?

Precisely monitor, control, and visualize every aspect of your operations for intelligent control using high performance technology from Proficy HMI/SCADA, featuring our industry-leading iFIX and CIMPLICITY software. With a quick glance, operators know what's important and the right actions to drive increased efficiency and reduced costs.

Explore tips and best practices for modern HMI/SCADA in our Guidebook for Efficient Operations.

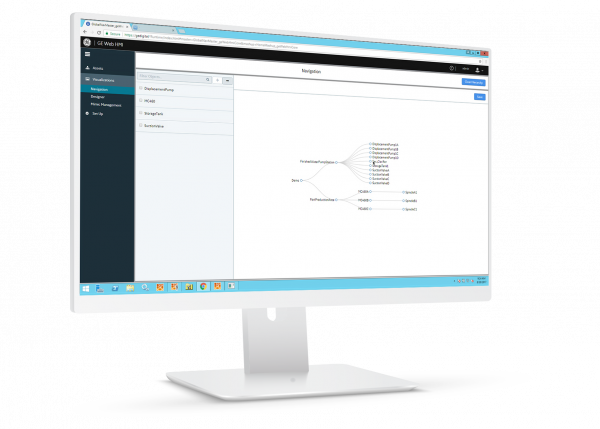

New generation iFIX and CIMPLICITY with native HTML5 & MQTT

Proficy 2023 webinar series

Explore new generation software with native HTML5 with Proficy Operations Hub, MQTT, and Configuration Hub for common authentication and modeling.

- Easily combine iFIX or CIMPLICITY with other OT/IT systems via Proficy Operations Hub for a richer operator experience

- Common model to reduce configuration

- TCP/IP-enabled Failover for architectural flexibility and disaster recovery

- MQTT5 client brings data from smart IoT sensors/devices into SCADA and subscribes to MQTT message bus data

Java-based HMI/SCADA: Is it worth the risk?

Java-based HMI/SCADA systems offer an OS-independent product. However, some Java-based HMI/SCADA systems do come with disadvantages. Understand the potential risks of Java-based HMI/SCADA versus solutions such as GE Digital's iFIX and CIMPLICITY HMI/SCADA.

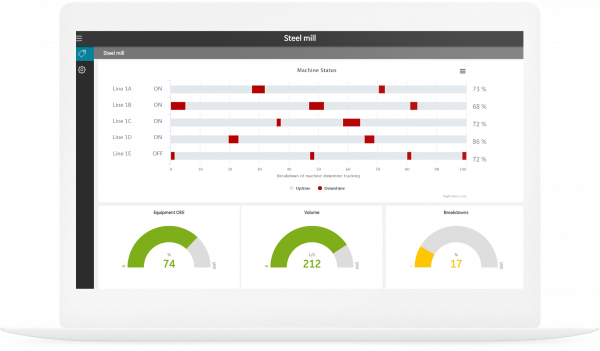

Scalability in Automation: Who's the weakest link?

From a single machine to a complete factory, automation solutions range from a few I/O points to millions. Understand how to scale your automation system. We highlight a remote monitoring and control application to showcase how to overcome mobility challenges. Learn how you can prevent your automation system from becoming the weakest link in your operations.

Benefits of GE Digital's HMI/SCADA

Less time spent navigating

Faster finding critical data

Improvement in alarm resolution success

Faster to identify relevant screen for an alarm

Increase in usability

Faster build and deployment

Faster response for operators, faster development for engineers

Faster response for operators, faster development for engineers

Hear from our HMI/SCADA customers

Testimonials

Explore HMI/SCADA products

iFIX

Gain visibility into your operations and secure agility for smarter decision making that drives results.

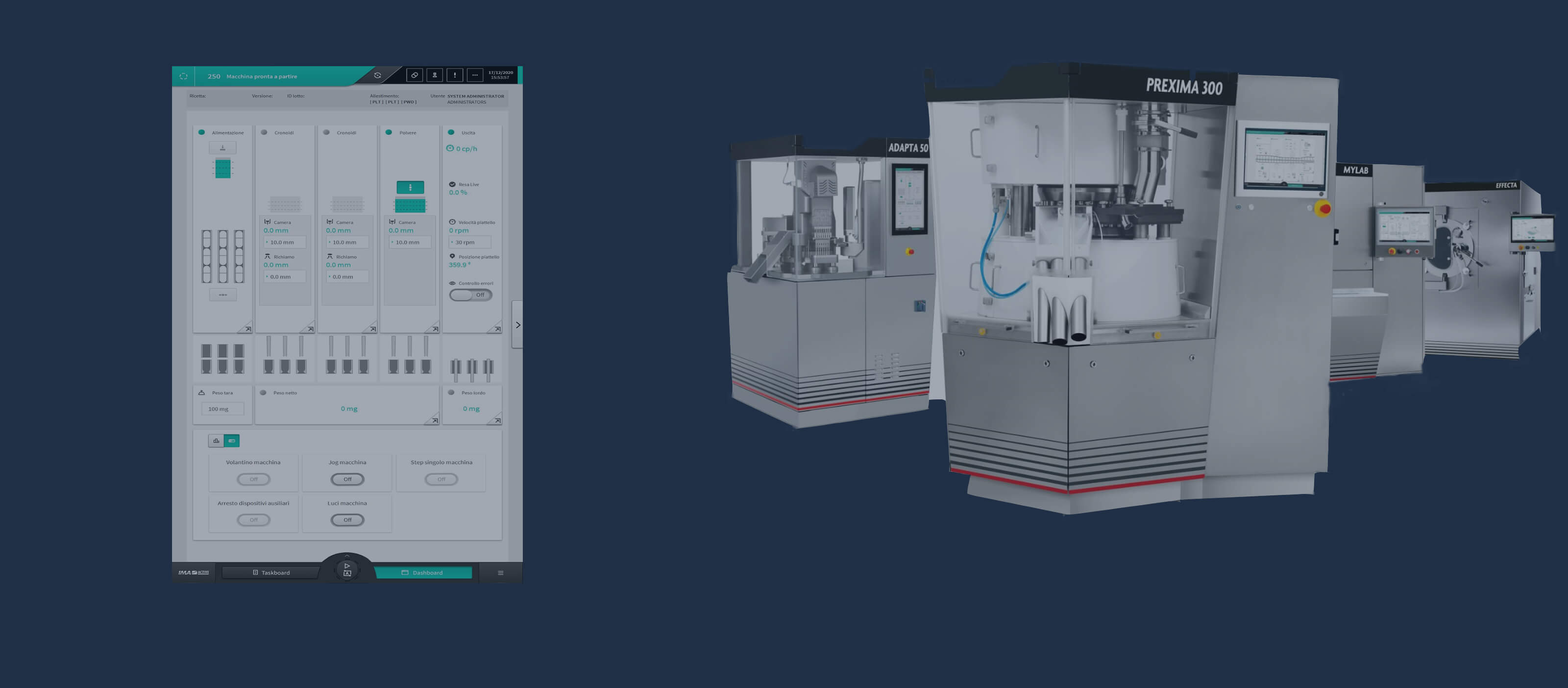

CIMPLICITY

Drive real-time visibility for smart operators with true client-server-based visualization and control.

Proficy Workflow

Guide operators with dynamic, interactive electronic work instructions and eSOPs for consistent operations and optimized processes.

Proficy Operations Hub

Speed development of Web-based operations displays with code-free configuration

Are you running your plant operations with serious risk?

Check the expiration date

Most industrial applications lack recommended updates and security patches, which make them a target for hackers. Outdated architectures, backups and spares can also create problems. With the number of attacks on industrial applications rising and the critical need for plant system availability, take simple steps now to minimize risk. You can decrease unplanned downtime while helping to protect your organization. Here’s how…

Get the most out of your HMI/SCADA software

Already purchased our HMI/SCADA? GE Digital is here to make sure you get the most value from your software.

View Demo

Let GE Digital show you how to improve your operations with today's HMI/SCADA