Boiler Plant Optimization for Steam Plant Efficiency

GE Digital’s BoilerOpt software offers steam plant operators real-time optimization data for boiler systems to help minimize emissions, outages, and…

Operations Performance Management (OPM) for Power Generation

Increase revenue and margins with visibility, insights, decision support and advanced edge controls to optimize performance across your generation fleet

Download datasheet

Operations Performance Management (OPM) improves the performance of plants, sites, and generation portfolios with Performance Intelligence, Production Planning and Performance Optimization.

Enabled by secure edge-to-cloud technology and built on the Predix Platform, OPM analyzes historical data, plant operations and other data sources to monitor and diagnose issues or areas of improvement, predict capacity and its cost to improve day ahead and intraday planning, deliver executable advice or close the loop and drive desired outcomes for improved efficiency, flexibility, capacity and emissions.

Maximize plant production and margins through efficient and flexible production planning and performance monitoring and diagnostics processes.

Out-of-the box key performance indicator (KPI) catalog of thermal performance and financial calculations help enable faster time-to-value.

Leverage improved performance, capacity and heat rate predictions that project cost, revenue, and margin to meet financial targets.

Build certainty that your operating plan will optimize use of plant capabilities without impacting reliability.

OPM supports operational decision-making so power generators can rapidly respond to market demands. It provides accurate, clear, and complete situational awareness to help maximize outcomes.

Check out our OPM video demo series. See for yourself the power of OPM to reduce costs, streamline processes and unify your operations.

Achieve operating targets with key performance indicators (KPIs), scorecards and analytics-based advisors.

What traders and plant operators have traditionally lacked are comprehensive, timely and accurate data and tools that provide an integrated single source of truth to make sense of it all. Only with a complete picture of the operations, maintenance and actual capability of a power plant, coupled with market and environmental conditions, is it possible to make decisions about dispatch that maximize revenues while reducing fuel and maintenance costs.

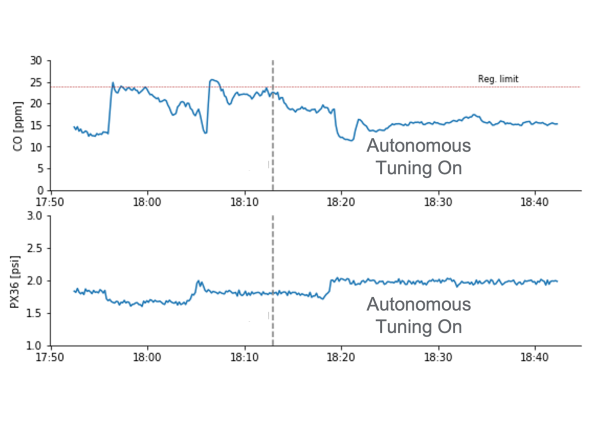

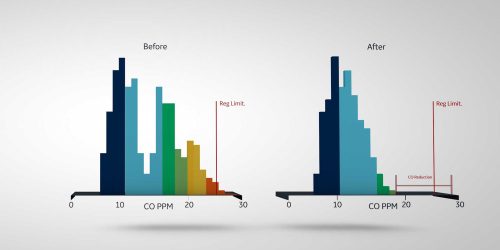

Fewer Emissions & Less Fuel – Every Two Seconds

Autonomous Tuning is an on-premises solution that uses artificial intelligence and machine learning (AI/ML) to continually find the ideal flame temperatures and fuel splits for optimal combustion. The software senses changes in ambient temperature, gas fuel properties and degradation, and sends real-time adjustments to the controls every two seconds. The Level 2 software is fully bound by the controls system safety-critical programming and is unable to harm the turbine.

Safely expand operating limits with optimizers and advanced edge controls to enhance dispatch position by improving efficiency, generate more revenue with increased output, achieving faster starts and reducing emissions, and thrive in the marketplace by responding more flexibly to diverse market conditions.

See how to flex your gas plant to meet dynamic market demands with Capacity Optimization software

Maximize margins and manage risk with accurate capacity predictions and decision support.

GE Digital is offering a free trial for a limited number of companies to experience one of Production Planning’s core technologies, Price Prediction.

GE Digital’s BoilerOpt software offers steam plant operators real-time optimization data for boiler systems to help minimize emissions, outages, and…

Generate more power with less emissions and fuel

Help ensure worker safety and operations continuity with secure remote operator controls.