Japan presides over a highly developed economy, yet, lacking abundant domestic energy sources, it remains reliant on the costly import of coal, oil, and natural gas in the form of liquefied natural gas. But what if there was a way to import energy that’s a lot cleaner? And not only to Japan but all of Asia?

One surprising path: ammonia. Under a new memorandum of understanding, one of Japan’s longest-established manufacturers, IHI Corp., and GE will work in cooperation to develop technology to use ammonia as a fuel. The goal is to allow some of GE’s existing gas turbine products to safely burn 100% ammonia by 2030 to reduce carbon emissions. That could eventually lead to a broader vision that IHI describes as “the ammonia society,” where hydrogen-carrying ammonia would become a way to store and deliver imported energy — or what IHI calls “shipping sunshine.”

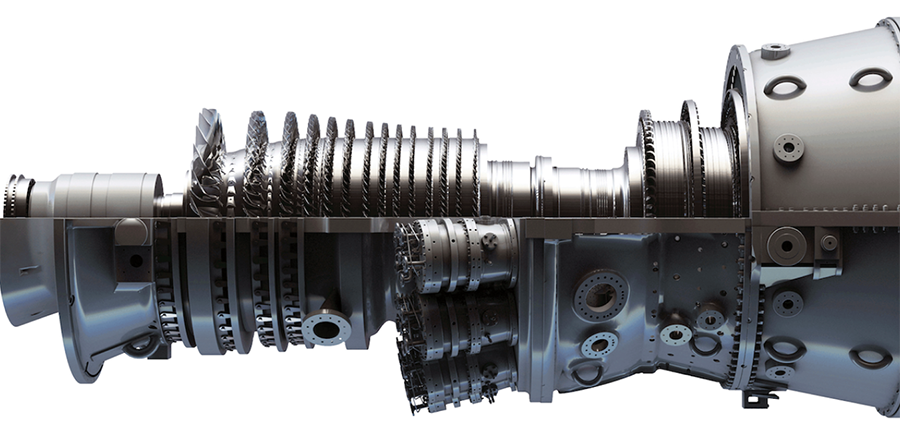

GE has been working with IHI for two years now, studying the economics of utilizing ammonia as a fuel in Japan. Used abundantly as a fertilizer in agriculture, ammonia’s components — hydrogen and nitrogen — offer intriguing promise as a fuel in several ways. One potential avenue is to combust it directly in a turbine to generate electricity, replacing natural gas. To that end, GE and IHI, a leader in ammonia combustion technologies, agreed in January to develop an equipment retrofit package for GE’s heavy-duty 6F.03, 7F, and 9F gas turbines, enabling them to burn ammonia.

Transitioning to a new fuel goes beyond a reconfiguration of natural gas turbines and impacts the broader ecosystem that surrounds them. “At General Electric we sell a customer a whole system, a whole power plant,” says Jeffrey Goldmeer, emergent technologies director for GE Power, one of GE Vernova’s portfolio of energy businesses. “And we have to make sure all the power plant systems work with ammonia.”

Another way to utilize ammonia is to make it a carrier for energy. In this scenario, ammonia would be shipped to countries like Japan and, again, it would be combusted directly in turbines as a fuel, or its embedded hydrogen could be “cracked,” or separated out, and then used to power turbines.

This idea faces many challenges, of course. One is the cost of shipping ammonia versus shipping hydrogen, a topic GE and IHI have been studying. Their conclusion: It’s less expensive to ship ammonia. Shipping hydrogen requires converting it to its liquid form, which means getting its temperature down to an ambitiously low minus 250 degrees Celsius (–418 Fahrenheit). “There’s only one ship in the world today that can move liquid hydrogen, and it’s basically a ship that was built to demonstrate the concept,” says Goldmeer.

But it’s easier to move ammonia, because changing it from gas to liquid requires cooling it down to a temperature of only minus 30 Celsius (–22 F). And there’s already a well-established global shipping network for ammonia. “Somewhere between 15 and 20 million metric tons of ammonia are shipped around the world today,” Goldmeer says. (For context, liquefied natural gas must be cooled to roughly –162 C (–260 F), but the U.S. alone exported some 74 million metric tons of LNG in 2022.)

The broader challenge is making ammonia in a way that doesn’t emit as much carbon. Producing ammonia, a process that typically uses fossil fuels, is a significant contributor to CO2 emissions, accounting for about 1.3% of all emissions in the energy sector, according to the International Energy Agency, which recently published a report examining the economics of using ammonia as a transport option for hydrogen. One of the main areas of focus in the IEA report is how ammonia might be made using electrolysis or methane pyrolysis, two ways to potentially produce hydrogen with lower carbon emissions, thus lowering the carbon intensity of the final product.

A cleaner path does exist. Although the IEA says these alternate methods could cost 10% to 100% more per ton of ammonia, the same can be said for other technologies such as producing hydrogen via electrolysis, or adding carbon capture and sequestration to steam methane reforming. The question, Goldmeer says, is which of these fuels that produce little or no carbon during combustion could yield the lowest delivered cost. “Based on the assumptions we used in the study,” he concludes, “ammonia could be a lower-cost option.”

And he says there’s an even bigger picture to consider, especially for GE, which has been operating in Asia for over a century. “Japan is really a surrogate for countries in Asia that are dependent on imports of carbon-based fossil fuels,” he says. “So, whether it’s Japan, Singapore, South Korea, all of a sudden we’ve got multiple countries thinking about the potential importance of lower-carbon fuel sources. And ammonia, based on this analysis, seems to be a rational choice.”

Top: One of GE Gas Power’s heavy-duty 7F gas turbines. Credit: GE Gas Power